Vaccination

Maskon vaccination system - Revolutionizes and streamlines fish vaccination!

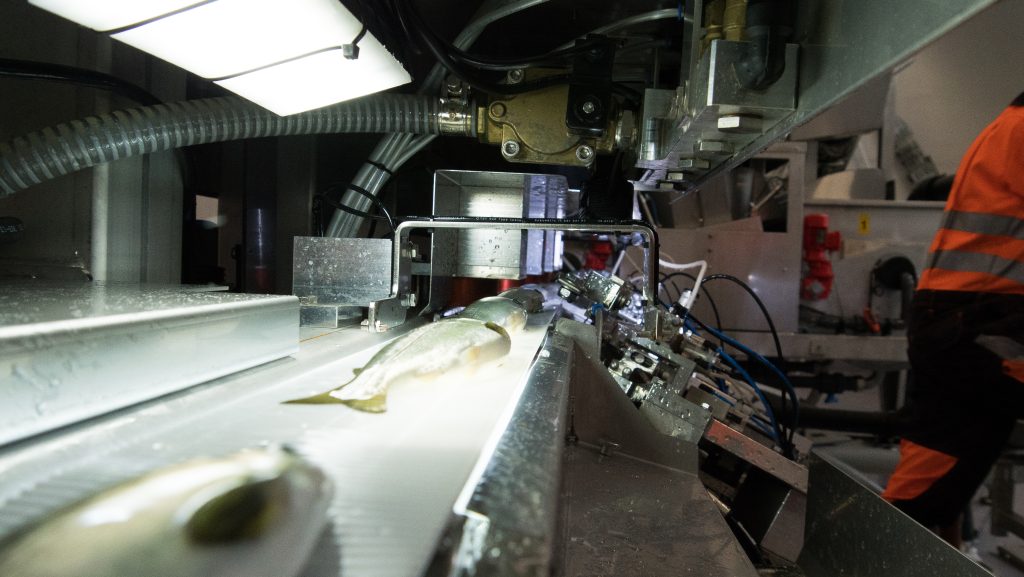

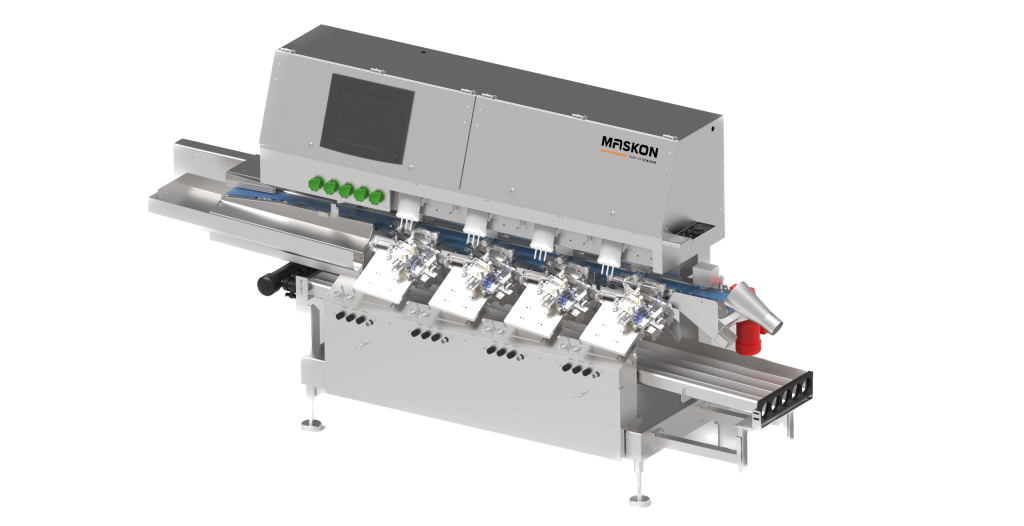

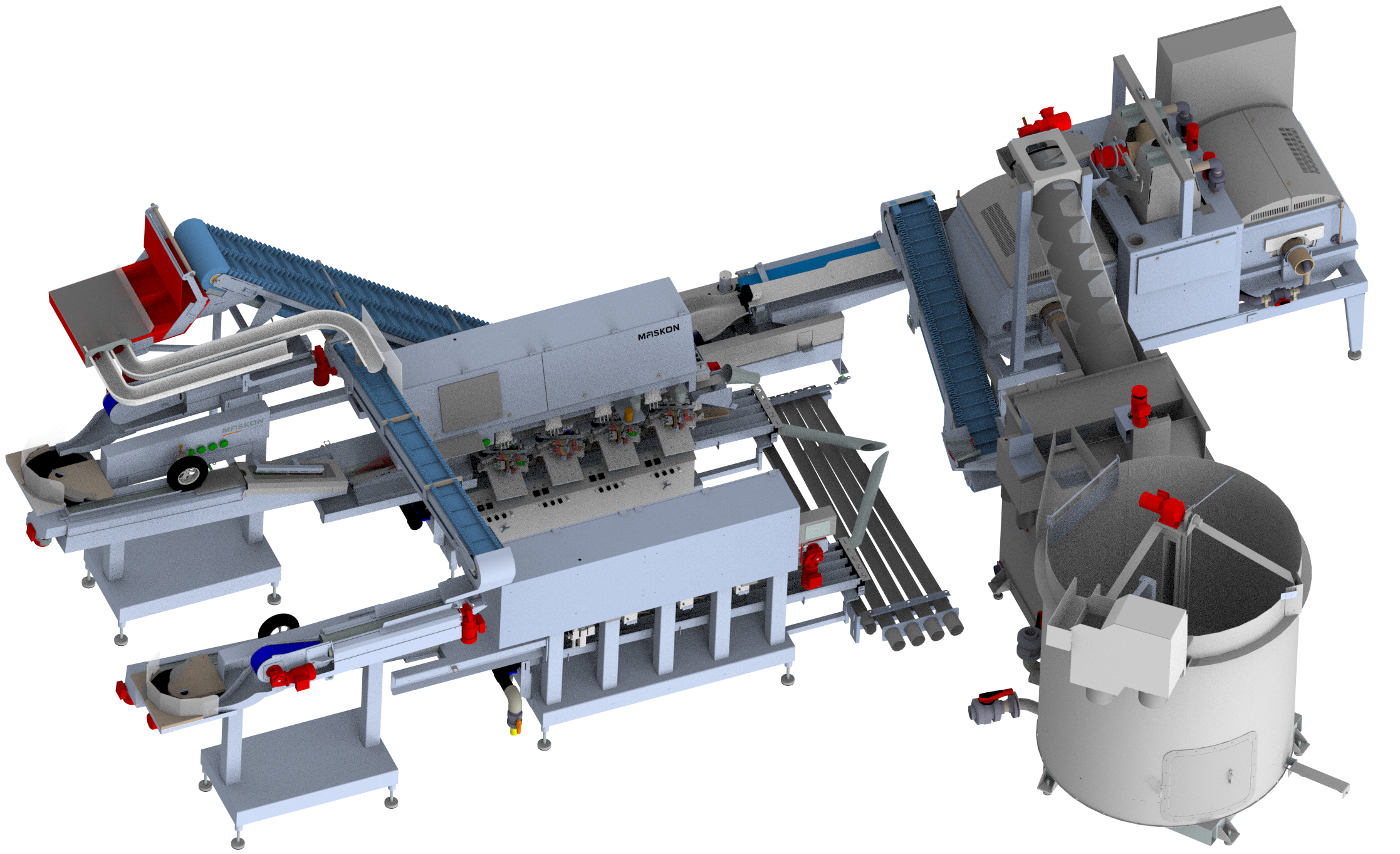

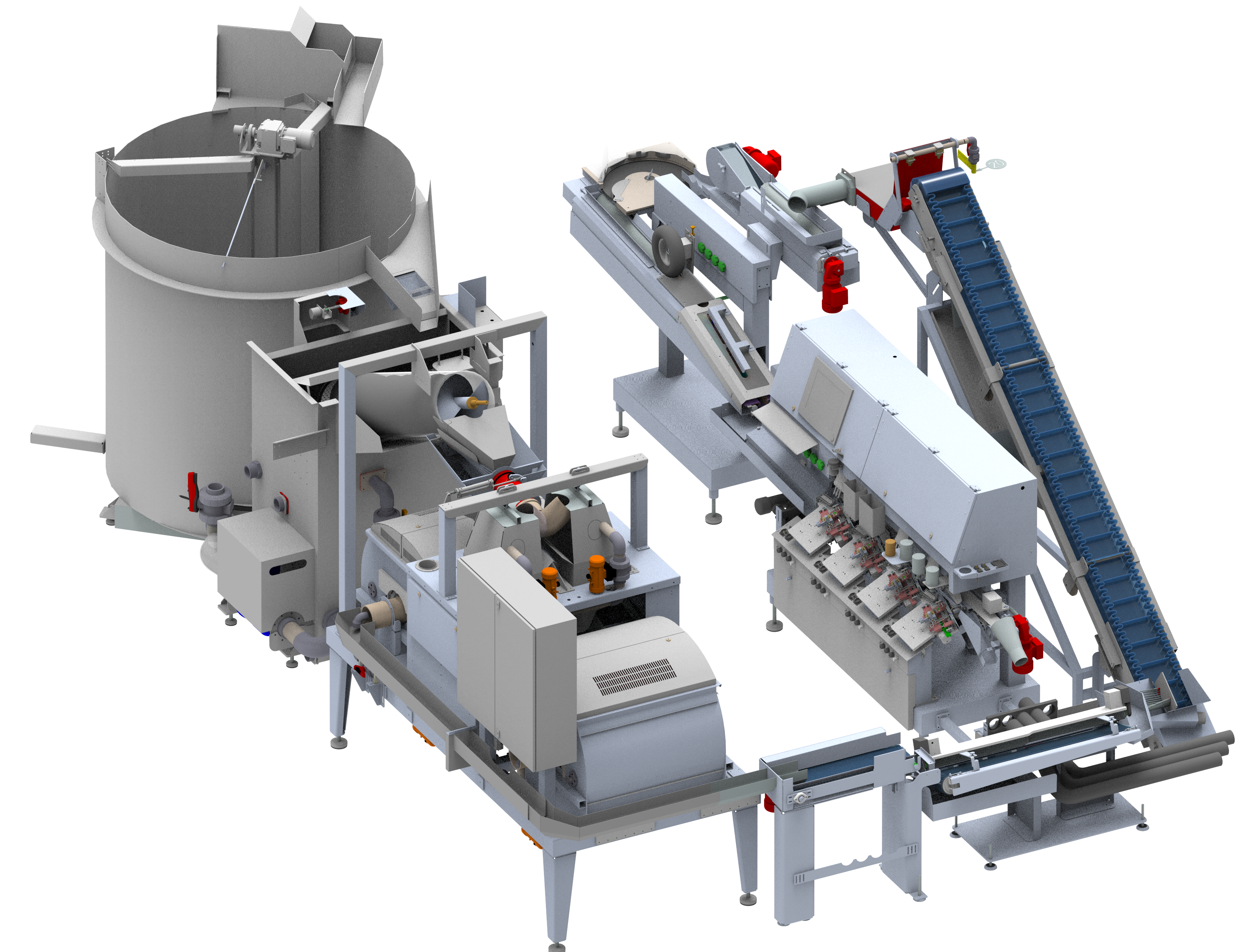

The Maskon vaccination system has been developed in close collaboration with the world's largest salmon producers. Maskon's fully automated vaccination machine can be operated by a single operator and can vaccinate and sort up to 40,000 smolts per hour. The machines can vaccinate up to 4 different vaccines simultaneously, either in the belly or intramuscularly.

Product Details

VX16

VX8

VX4

VX4 W/batch anaesthetic device

Capacity

40 000 fish/h*

Power supply

6 x 16A 400VAC

Air pressure

8 bar

Airflow

2m3/min dry and clean air

Water supply

4 bar 30m3/h, 1 bar 70m3/h

*Depending on the batch composition and other peripheral equipment.

Capacity

20 000 fish/h*

Power supply

3 x 16A 400VAC

Air pressure

8 bar

Airflow

1m3/min dry and clean air

Water supply

4 bar 15m3/h, 1 bar 35m3/h

*Depending on the batch composition and other peripheral equipment.

Capacity

10 000 fish/h*

Power supply

2 x 16A 400VAC

Air pressure

8 bar

Airflow

1m3/min dry and clean air

Water supply

4 bar 7,5m3/h, 1 bar 30m3/h

*Depending on the batch composition and other peripheral equipment.

Capacity

10 000 fish/h*

Power supply

16A 400VAC

Air pressure

8 bar

Airflow

1m3/min dry and clean air

Water supply

4 bar 7,5m3/h, 1 bar 5m3/h

*Depending on the batch composition and other peripheral equipment.

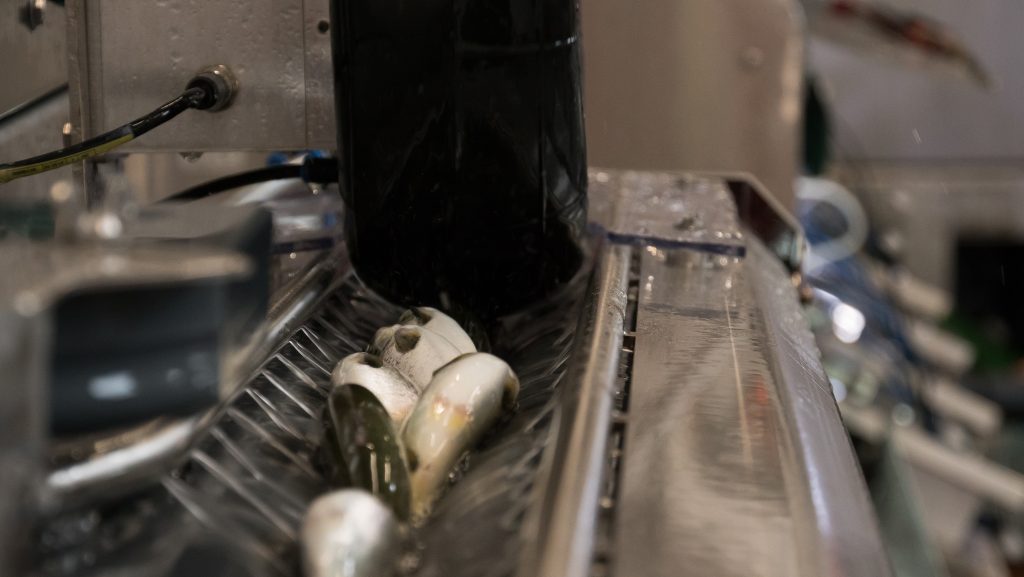

Maskon’s automatic vaccination machine can be operated by a single operator. It is designed to handle fish in the size range of 30-130 grams (larger fish can be handled with some simple modifications). The machine will singularize and orient a batch of anesthetized fish, and using machine vision, ensure correct vaccination. The machine is user-friendly, reliable, and designed to take into account hygiene and animal welfare considerations. The maximum capacity for the largest unit is up to 40,000 smolt per hour.

VX-4, VX-8 & VX-16

The benefits of Maskon’s vaccine machines are:

- Modular machine that is easy to integrate and easy to expand.

- Solution is customized to available space.

- Very high vaccine quality.

- One operator, easy operation and high uptime.

- Automatic weight sorting and sorting

- Monitoring, service, and support.

High efficiency as a complete solution.

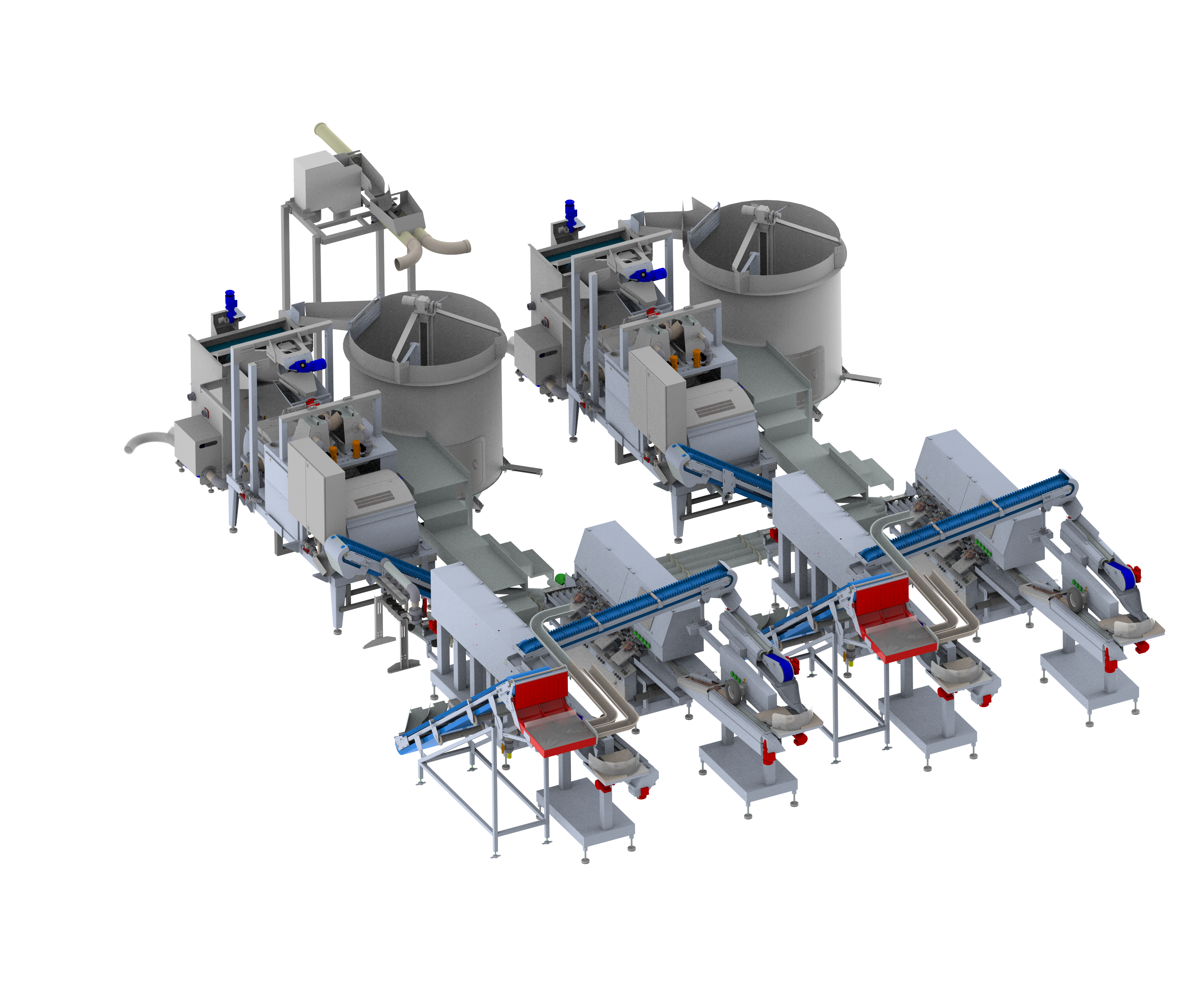

Maskon’s anaesthetic device and buffer tank enable automatic supply of fish to the vaccination machine. Data from the vision system is used to calculate the average weight of the fish and determine the amount of fish to be delivered to the vaccination machine.

The system accurately weighs the fish before sending them to the anaesthetic device, ensuring a precise amount of fish is delivered at all times. Fish are fed to the anaesthetic device with an Archimedes screw, which allows for fast and easy regulation of the feed rate. This method is gentle on the fish during transport.

Maskon’s anaesthetic device consists of 2 chambers, which prevents downtime when switching anesthesia. The buffer tank and anaesthetic device communicates directly with our vaccination machine, ensuring no limited interfaces.

By utilizing our fish pumping system, the entire system will work together seamlessly, resulting in a highly efficient, gentle, and simple vaccination process.

Questions?