Egg sorter

Previously, it has been a manual task to sort out eggs that are either unfertilized or where the salmon embryo has not developed properly.

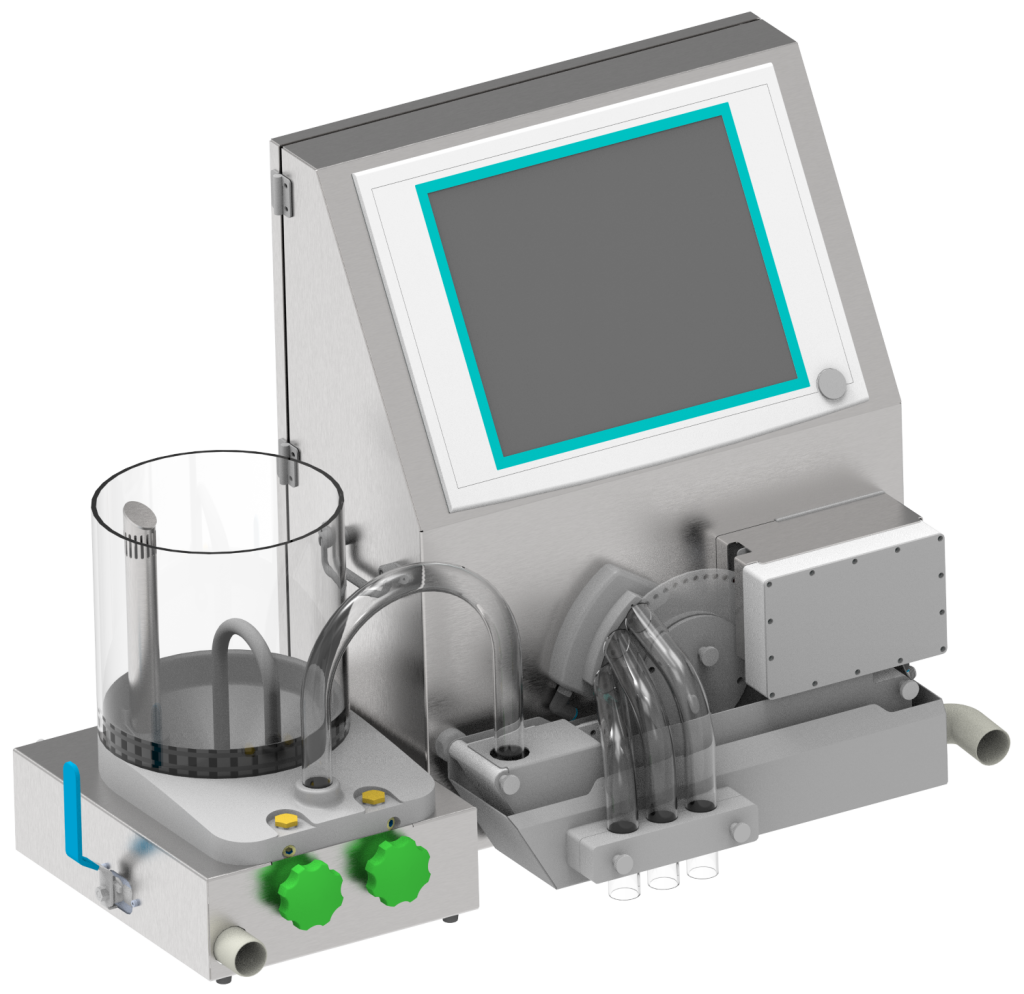

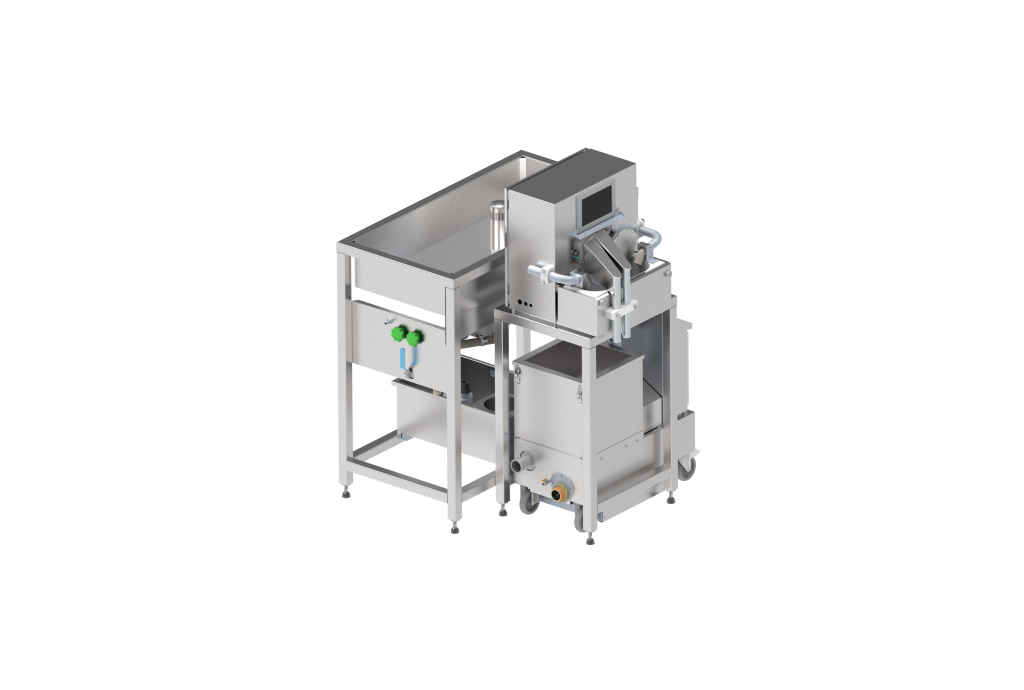

With Maskon's Egg Sorter, this can be done significantly faster and more accurately than if done manually. The egg sorting machine has now been further improved in this new and more compact version.

Product Details

Capacity

Upto 140 000/hour

Power supply

230 VAC 10A 1-phase

L x W x H

980 x 470 x 690 mm.

Weight

70 Kg

Air

Approx. 20 l/min. Minimum 2 bar

Water

Approx. 10 l/min. Minimum 2 bar

Hole size disc

3 - 9 mm.

Labor and cost-saving.

Experience shows that the Maskon Egg Sorter replaces existing technology for mechanical sorting and eliminates the need for manual sorting. A monotonous and tiring task that has become difficult to find people to do is thus eliminated. The product becomes faster “ready to market” and you save valuable work hours for manual sorting. The machine can be integrated into a modern transport system for eggs, or set up as a “stand alone” unit with its own tank. One operator can operate multiple machines or have other tasks in addition. Thus, this can quickly become a profitable investment. The machine has a capacity of up to 140,000 eggs per hour.

To further increase efficiency, we have also developed a rough sorting machine that removes only the dead eggs. That machine has a capacity of about 1 million eggs per hour.

Increased accuracy and better quality!

The machine takes up to 6 images of each individual egg, as needed – from both sides of a feeding wheel. A computer then assesses the quality of the roe grain based on several criteria; unfertilized, small eyes, size, coagulations, and of course dead eggs.

Detailed reporting

As Maskon Egg Sorter is based on data analysis, it is easy to extract statistics and reports such as the number of eggs distributed by quality and size, etc. The machine is also prepared for database management. The report is detailed and is a very nice documentation to include with the delivery.

Questions?